Despite the great success of organic photovoltaics in terms of device efficiency and stability at the laboratory scale, pressing demand for high-throughput and cost-effective solutions remains unresolved and rarely reported. Here we propose that a sequential-deposition, blade-coating approach using donor and acceptor materials can facilitate high-speed fabrication of photoactive layers while maintaining device performance. The sequential-deposition-processed blend and thickness of its designed PM6:T8 system can be optimized by the fine-tuning of the solution concentrations and coating speeds. We show that this strategy can be applied to a non-halogenated solvent and under high-humidity conditions. This high-speed approach is applicable to other non-fullerene photovoltaic systems and the slot-die coating technique. Techno-economic analysis suggests that this strategy can decrease the minimum sustainable price of module manufacturing. Overall, this work represents a step towards the scalable, cost-effective manufacturing of organic photovoltaics with both high performance and high throughput.

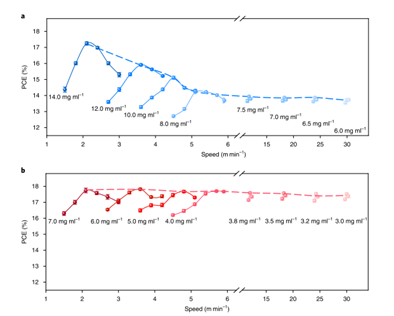

Figure 1. Photovoltaic properties and device stability. Extracted solar cell PCEs of the (a) BHJ-processed devices and the (b) LbL devices. The dashed lines represent the PCE trend. The error bars represent the s.d. of independent measurements from ten devices.

This work was supported financially by the National Natural Science Foundation of China (grant numbers 52061135206 and 22279094 to J.M.) and Fundamental Research Funds for the Central Universities (to J.M.). We thank the Core Facility of Wuhan University for the optical microscope and AFM measurements.

Original link: https://doi.org/10.1038/s41560-022-01140-4